There are a number of addressing schemes used by PLC manufacturers. Let’s take a quick look at how memory locations (including hardware I/O) are accessed with RSLogix 500. Along the way, let’s define some terms.

Offering more than 100 shades of professional quality cosmetics for All Ages, All Races, and All Genders. Enjoy free shipping and returns on all orders. If you need help when using RSLogix 5, use any of the following methods:. Choose Help from the menu bar. Click Help in any RSLogix 5 dialog box. Press F1 on any instruction, dialog box, or window view. For more information about the online help, see. RSLogix 5 online help on page 111. Search RSLogix Micro Starter Lite w/o RSLinx EN (8.30.00) Click on “Add to Download Cart” Click on “Downloads” Click on “Download Now” Accept “ User Agreement” Click on “Direct Download” Final Ste p: Click on “Micro Lite 830.zip.exe” which is the download link For RSLinx Classic. Working with our industrial automation customers throughout the San Francisco Bay Area, at times we see customers struggling with managing their software licenses between users. Most Rockwell Automation software licenses are single seat, which means they can only be used by one person at a time. Occasionally, however, there are times when you might not have access to the computer with the.

INSTRUCTION – RSLogix’s command language is comprised of “instructions”. An XIC (it looks like a normally open contact –] [– ) is an instruction. A timer is an instruction. A few of the most common instructions are described below.

BIT – an address within the PLC. It can be an input, output or internal coil, among others.

In RSLogix, there are a couple of ways to show the address of a bit. The default is:

Rslogix 500 Macro

[type]:[word]/[bit]

For example, an address that references an output of a MicroLogix 1100 is O:0/0. That is:

O:0/5 means that it is a physical output.

O:0/5 means that it uses Slot 0 (in the case of the 1100, this output is onboard)

O:0/5 means that it is the fifth output on the PLC.

Universe sandbox 2 full game free download. By the way, don’t get the capital “O” confused with a zero.

RUNG – A section of the PLC ladder program that terminates in an output function of some type. Just like in an electrical ladder diagram, a rung has some type of output that is turned on or turned off by the preceding entities in the rung. The first rung in a ladder program is always 0000.

HARDWIRED INPUT – a physical connection to the PLC from an input device (switch or sensor, etc.).

Allen-Bradley uses the capital letter “I” to designate a hardwired input. An address that describes an input on an SLC 500 is I:4/0.

Similar to the output structure,

I:4/0 means that it is a physical input.

I:4/0 means that it uses Slot 4 (the 5th slot in the rack).

I:4/0 means that it is the first input on the card.

Don’t get the capital “I’s” confused with ones.

HARDWIRED OUTPUT – a physical connection from the PLC to an output device (relay or pilot light, etc.) As was said above, an address that references an output of an SLC 500 is O:5/0.

INTERNAL COIL

This is a programmable bit used to simulate a relay within the PLC. The internal coil has no connection to the outside world. It does not connect to an output card. Internal coils are used to store information. The “contacts” of this “relay” can then be used multiple times in other parts of the program.

In RSLogix, the “B3” (binary) file is commonly used for all the internal coils. There are many other words in other files that have bits you can use as internal coils, but we are going to stick with the B3 file for our application.

B3:0/0 means that it references an internal Binary file

B3:0/0 means that it uses the first word in the table

B3:0/0 means that it is the first bit in the word.

Note that, unlike the Output and Input files, you have to use the file number in the address. In this case, the default file number is 3.

TIMER

A timer is a programmable instruction that lets you turn on or turn off bits after a preset time.

The two primary types of timers are TON for “timer on delay” and TOF for “timer off delay”.

Timers in A-B SLC and MicroLogix processors use file 4 for their timers.

T4:0 means that it references an internal Timer file

T4:0 means that it uses the first timer in the table

The address T4:0 simply refers to the timer. Each timer has bits that turn on after the timing function is complete. You can address this bit by simply putting a “/DN” after the timer address. DN stands for “done”.

For example, if timer T4:0 is a TON (timer on delay), then the bit T4:0/DN will turn on after the timer has reached its preset value.

COUNTER

A counter is a programmable instruction that lets you turn on or turn off bits after a preset count has been reached.

There are different types of counters available in the RSLogix, but the CTU (counter up) instruction covers everything we will talk about here.

Counters in A-B SLC and MicroLogix processors use file 5.

C5:0 means that it references an internal Counter file

C5:0 means that it uses the first counter in the table

The address C5:0 simply refers to the counter. Each counter has bits that turn on after the counting function is complete. You can address this bit by simply putting a “/DN” after the counter address. DN stands for “done”.

For example, if counter C5:0 is a CTU (counter up), then the bit C5:0/DN will turn on after the counter has reached its preset value.

–] [– Normally Open Contact

When used with a hardwired input, this instruction is off until there is a voltage applied to the input. The bit address then goes high, or on, and the instruction becomes “true.” It works the same way when it has the same address as an internal coil, except that the coil must be turned on by logic in the program.

Allen-Bradley calls these normally open contacts “XIC”, or “eXamine If Closed” instruction.

An XIC instruction can reference a hardwired input, a hardwired output, an internal coil or a timer done bit, among others.

–]/[– Normally Closed Contact

This is an inverted normally open contact.

When used with a hardwired input, this instruction is “true” until there is a voltage applied to the input. It then goes low, or off, and becomes “false.”

It also can be used with an internal coil, becoming true when the coil is off and becoming false when the coil is on.

Allen-Bradley calls these normally closed contacts “XIO”, or “eXamine If Open” instructions.

-( )- Output Coil

When used with a hardwired output, this function is off until the logic in the program allows it to turn on. It then becomes “true”, and will energize the device that is wired to the respective output.

If it is used as an internal coil, it will toggle the instructions associated with it. That is, it will close a normally open instruction and open a normally closed instruction.

Allen-Bradley calls these outputs “OTE”, or “OutpuT Energize”.

An OTE may be used with a hardwired output or an internal coil.

TRUE – A state that indicates an instruction is allowing logic to “flow” through it.

Also, if the logic in a rung turns on the output of the rung, then the rung is said to be true.

FALSE – Without stating the obvious, this is the opposite of true.

Excerpted from PLC Programming with RSLogix 500

I have been programming Programmable Logic Controllers (PLCs) for the last 5 years. I’ve finally decided to take some time and share the knowledge I’ve acquired over the multiple roles I had within manufacturing sites.

Arren Bradley has been my platform of choice due to the fact that I’ve received critical training focused on these controllers early on in my career.

As an Electrical Engineer, I had never taken a class on PLCs before I started working. Furthermore, I had no idea what they were. It seems that the industrial manufacturing industry is extremely secretive about the technology and has a hard time training younger individuals on their technology. However, there is a massive gap between what is industry needs in terms of individuals who know these systems and graduates coming out of universities and trade schools.

Many opportunities exist in the manufacturing sector which requires some knowledge of PLCs, HMIs, and other control related technologies.

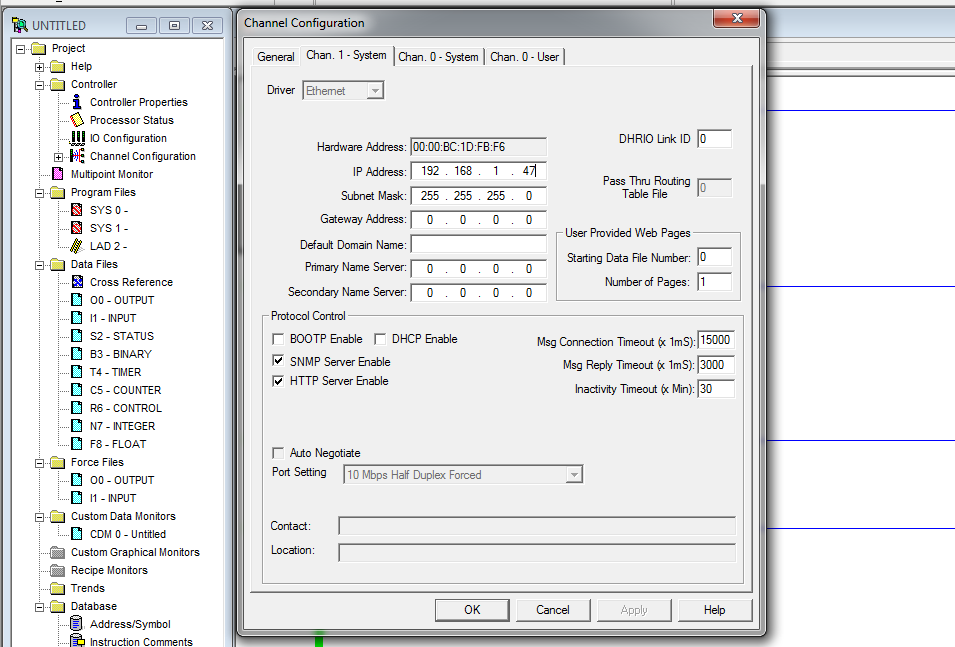

In this first tutorial, I will be covering the process of connecting to a brand new MicroLogix 1100 PLC. This process may seem obvious, but presents quite a few challenges which I had to face many times.

Before we jump into the hardware, it’s important to verify the current settings on the processor.

Most PLCs are equipped with an LCD screen which will provide the user with information. In terms of connecting to the device, we’re looking for an IP address.

For a MicroLogix 1100 PLC, you will find this information in Advanced Settings > ENET Cfg.

Once you reach this settings page, you will be presented with information about the Physical Address (MAC), the IP as well as the Subnet Mask for the controller. For a brand new controller, the user will be presented with a screen which displays the MAC address only. It’s important to take a note of it as it will be used in BOOTP later in this tutorial.

It’s very important to get the computer settings right before you can talk to your PLC.

In case of a brand new PLC, it’s important to give our Network Card the opportunity to set the IP address based on what the PLC will supply. To do so, open the Control Panel, navigate to the Network Settings and set the IPv4 address to “Obtain an IP Address Automatically”. By selecting this option, you will be able to see the PLC through the BOOTP utility.

Once the setting takes effect, launch BOOTP from your programs and allow the computer to scan for connected devices.

Within a minute or two, you should see the PLC (by MAC address) listed within the window. Select the PLC, click “add relation” and enter an IP address of your choice. Verify that the IP was taken by the PLC by visiting the exact same screen as described above. At this point, you should see the MAC as well as the IP address in the settings screen of the PLC.

RSLinx is the networking communication tool for Allen Bradley hardware. It allows one to establish a connection to a PLC or any other device over Rockwell networks. Within the tool, one will find “drivers” which can be used to scan the network for miscellaneous devices.

In our case, the first step will be to connect the PLC to the computer (this step should have already been completed previously) and set the IP address of the PC to be on the same network. In my tutorial, I’ve set the IP address to be 192.168.1.40 for the PLC and 192.168.1.200 for the PC.

By adding an EtherNet/IP driver to the RSLinx software, I’m able to scan for the appropriate device and verify that a link has been established to my PLC. If there is no link, the PLC icon will be a red cross indicating that the signal is not reaching the device.

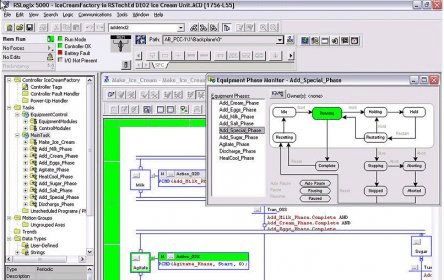

RSLogix 500 is an environment which allows one to establish a connection and program PLC devices. Although newer tools (such as RSLogix & Studio 5000) have been developed by Rockwell, RSLogix 500 is still widely used within the industry. For the most part, this tool offers the same capabilities as the newer versions. However, it’s much less intuitive and creates challenges for those who aren’t accustomed to working with it.

If you’re working with a brand new controller, it will have no program loaded on it. Therefore, go into “New”, select the type of controller you’re working with (in my case it’s a MicroLogix 1100) and create a blank program.

To connect to the PLC, go into “Comms” > “System Comms”, locate the PLC of your choice and hit Download (WARNING: downloading to a PLC will mean that you’re erasing absolutely everything that’s currently on it.). If there is already a program on the PLC, you should be using the Upload button which will transfer the program from the LPC onto your computer.

You’re now Online with the controller!

I must admit that going online can be tricky. This is partially due to the fact that this procedure is poorly documented and partially due to the fact that these tools constantly have issues. I did have to reboot and restart my tools on several occasions as everything seemed to be ok, but nothing was working.Rslogix State Machine

Once you’ve gone through the process a few times, it becomes much easier working with different kinds of controllers, RSLinx, BOOTP & RSlogix 500.

Cheers,

Vlad